|

|

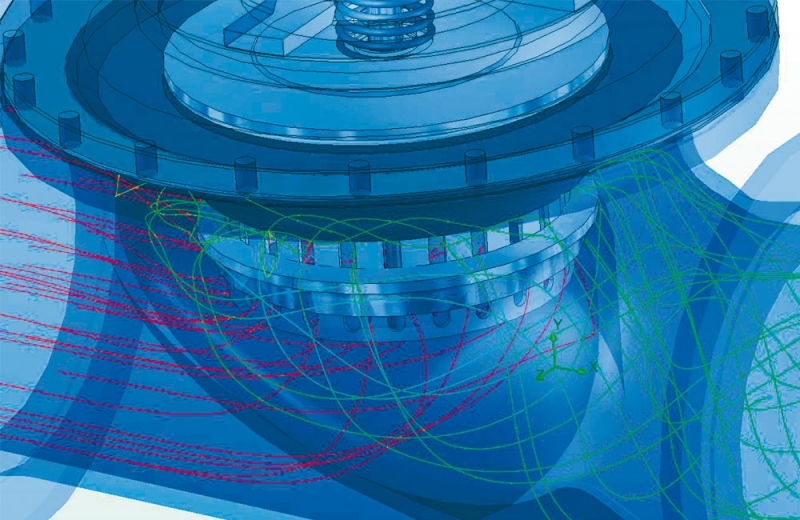

Cavitation has been a familiar phenomenon for a long time for valves and fluid control applications involving the areas of acoustics, hydrodynamics, thermodynamics, physics and chemistry. The consequences for a control valve are often destructive with loud noise, vibrations, vapor, erosion of the valve component.

CSA thanks to the use of advanced CFD, state of the art testing facilities and years of experience has developed a series of cages to prevent cavitation and ensure the maximum stability of the valve under low flow events.

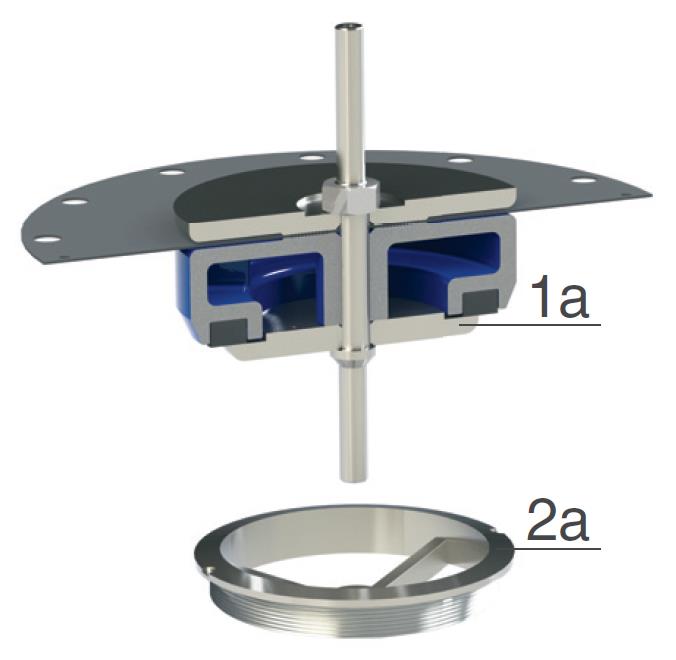

Above particular of CSA XLC 300 and 400 series.

The following options are available and interchangeable between one valve and the other:

|

Standard version of gasket holder and sealing seat |

|

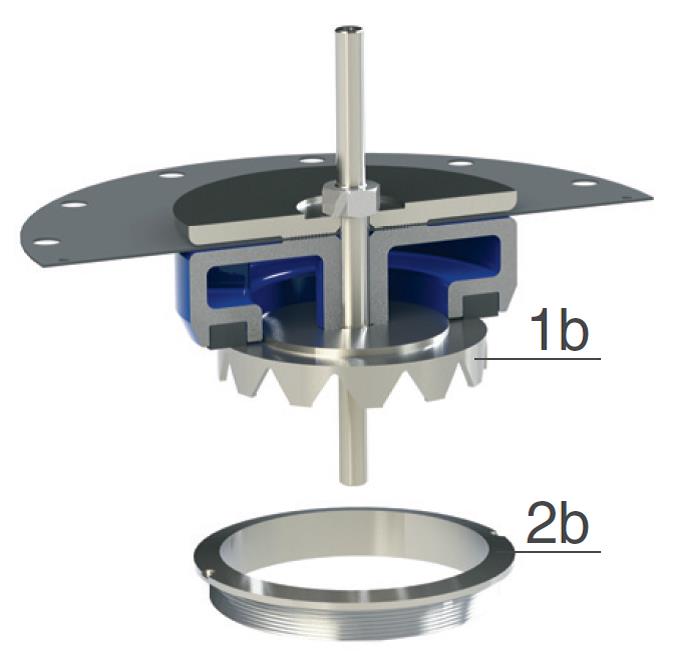

LF version for low flow stability The LF includes a gasket holder (1b) with progressive opening which allows for stability also in presence of extreme low flow values. |

|

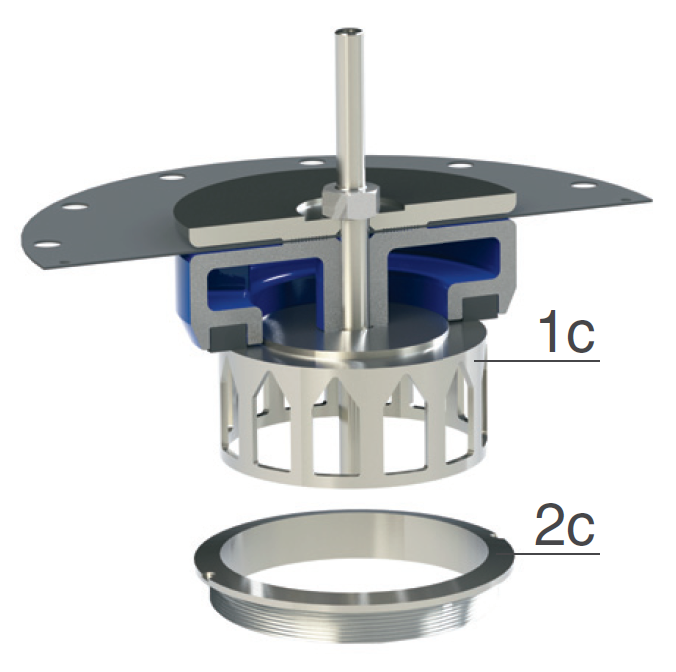

AC version for low flow and cavitation prevention The anti-cavitation trim AC mobile block includes a gasket holder (1c) designed to increase the allowable pressure ratio and resistance to cavitation. |

|

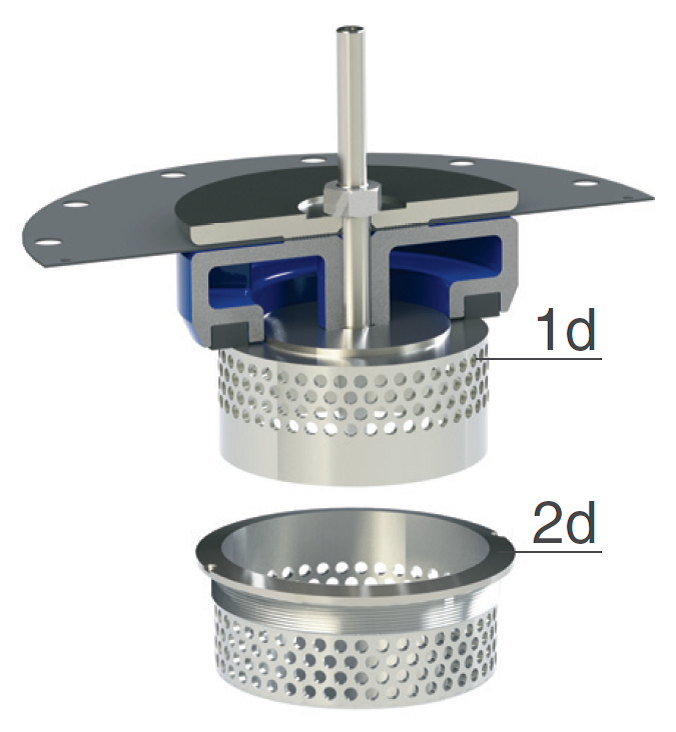

CP anti-cavitation version The CP system includes two cages (1d, 2d) for double energy dissipation between inlet and outlet. |

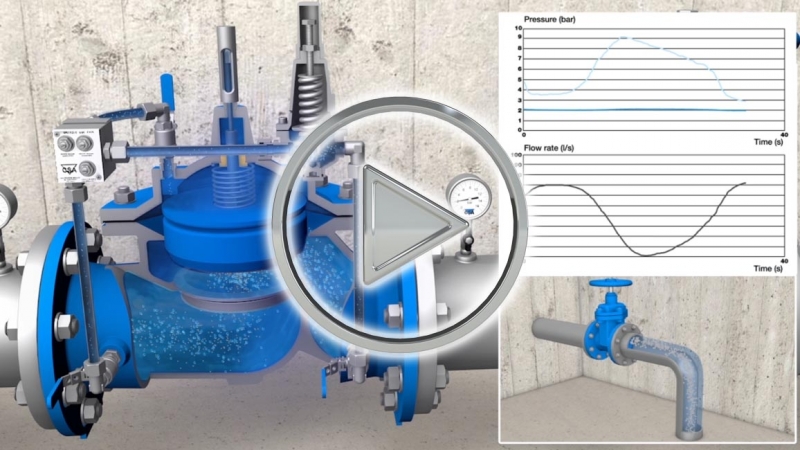

Detailed animations are available to grasp the proper operating principle of CSA automatic control valves, in particular to see the exclusive flow control device with built in filter entirely made in stainless GR.I.F.O., for independent opening/closing speed and reaction time regulation of the valve.