In order to prevent transients and unwanted damages on the pipeline systems we basically have to reduce the variations in velocity of the fluid and, when this happens, try to proceed as slow as possible.

It will therefore be mandatory to:

- operate slowly during valve operations, especially on the final position of the device.

- control the pipe filling through the use of anti-surge combination air valves, example the CSA RFP models.

- introduce air or water into the pipeline, at those locations where negative pressure conditions are likely to occur.

- adopt controlled pump start up procedures to avoid rapid changes in flow.

- carry out detailed computer analysis to evaluate and assess the risk associated to the system and transient events.

One of the best and most reliable solutions to the problem, and working as a standalone or in combination with other devices like anti-shock air valves and pressure relief valves, is the CSA air vented anti surge tank also called A.V.A.S.T.

This type of anti surge device can be installed in derivation from the main line or directly on top of it, and simply provided with an isolation device to allow for maintenance. No additional check valves, by pass or restrictions are needed. Compared to other solutions A.V.A.S.T. doesn’t need any kind of compressor, bladder or external source of energy. This means a reduced maintenance, higher reliability and, more important, a lower volume is needed to provide the same degree of protection, in comparison with bladder tanks or air vessels.

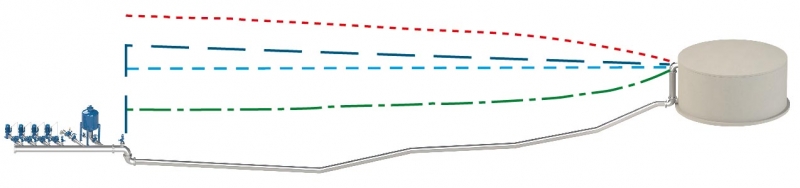

The plot above shows the pressure envelope of the transient event caused by pump failure on a pipeline with A.V.A.S.T. installed as a protection. The red and green are the maximum and minimum pressure values reached during the simulation, it is clearly visible the beneficial effect in terms of negative pressure and consequently reduction of water hammer.

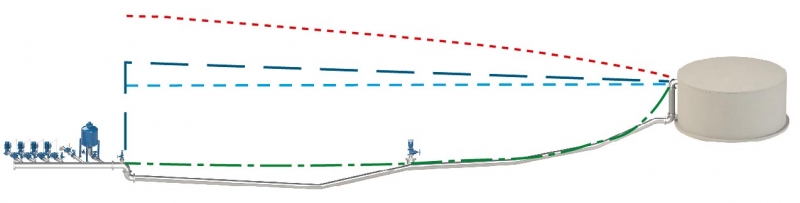

The plot above shows the pressure envelope of the transient event caused by pump failure on a pipeline with A.V.A.S.T. installed as a protection, in combination with anti-shock air valves (CSA AS series). In this case the effect of the air valve will help reducing the volume of A.V.A.S.T., containing budget and design requirements. The red and green are respectively the maximum and minimum pressure values reached during the simulation. Depending on the fluid A.V.A.S.T. can be placed at the pumping station or along the profile and calculated to perform with air valves and pressure relief valves, CSA VRCA series, if required.